Stainless steel is widely used in life and ranges from kitchen utensils to industrial equipment because it is a kind of durable, beautiful, and practical material. It can be regarded as one of the best materials due to its excellent performance in anti-corrosion and facility in cleaning.

How, then, do stainless steel products change from raw materials into various products we see being used in day-to-day life? Well, as a professional stainless steel food container manufacturer, I will use this article to provide you with a detailed introduction to the production process of stainless steel products, helping you understand each stage in detail.

Composition Of Different Grades of Stainless Steel

Stainless steel is a high-performance material based on iron with the addition of at least 10.5% chromium and other alloying elements (such as nickel, molybdenum, titanium, manganese, copper, etc.). Its unique corrosion resistance mainly comes from the presence of chromium in A protective oxide film formed on the surface. This film protects the steel from further oxidation, giving it excellent anti-corrosion properties.

At the same time, the addition of other alloying elements can improve the strength, toughness, high temperature resistance and processability of stainless steel.

According to different microstructures, stainless steel can be divided into austenitic stainless steel (such as 304 and 316, known for its corrosion resistance and formability), ferritic stainless steel (such as 430, high strength and low cost), martensitic stainless steel (such as 420, high hardness, suitable for making knives) and other types.

Although there are slight differences in the production process of these stainless steels, their manufacturing principles and basic processes are generally the same.

Parameters Of Different Grades Of Stainless Steel

| Grade | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

| 304 (Austenitic) | 18-20% | 8-10.5% | – | ≤ 0.08% | ≤ 2% | ≤ 1% | ≤ 0.045% | ≤ 0.03% |

| 316 (Austenitic) | 16-18% | 10-14% | 2-3% | ≤ 0.08% | ≤ 2% | ≤ 1% | ≤ 0.045% | ≤ 0.03% |

| 430 (Ferritic) | 16-18% | – | – | ≤ 0.12% | ≤ 1% | ≤ 1% | ≤ 0.04% | ≤ 0.03% |

| 410 (Martensitic) | 11.5-13.5% | – | – | ≤ 0.15% | ≤ 1% | ≤ 1% | ≤ 0.04% | ≤ 0.03% |

| 420 (Martensitic) | 12-14% | – | – | 0.15-0.40% | ≤ 1% | ≤ 1% | ≤ 0.04% | ≤ 0.03% |

What Is The Manufacturing Process Of Stainless Steel Products?

The production process of stainless steel products can be roughly divided into the following main steps:

Metal smelting

Melting is the first step in producing stainless steel, usually carried out in an electric arc furnace or a converter. At this stage, various raw materials, including scrap, stainless steel scrap, alloying elements (such as chromium, nickel, molybdenum, titanium, etc.) and iron ore are added to the furnace.

These raw materials are melted at high temperatures in the furnace to form molten metal liquid of stainless steel. During the smelting process, the temperature can reach more than 1500°C to ensure that all raw materials can be fully melted and reacted.

In this process, the control of temperature and chemical reaction in the furnace is crucial to ensure that the final stainless steel has a uniform composition and stable quality. The smelted metal liquid also needs to go through some refining processes to remove impurities and impurities to further improve the purity and performance of the stainless steel.

Precise control at this stage determines the chemical composition and properties of the final stainless steel, affecting the quality of subsequent processing and finished products.

The Continuous Casting Process

The refined molten metal is fed into the mold, cooled and solidified to form a rough steel billet (i.e., ingot). These rough steel billets are the basis for subsequent processing and can be cast into different shapes as needed, such as slabs, strips, tubes, etc., for further processing into various stainless steel products.

Traditionally, the casting process may use mold casting or static casting, but with the advancement of technology, the “continuous casting process” is widely used in modern production. The continuous casting process continuously pours liquid metal into the mold, which quickly solidifies and forms a steel billet with the help of a cooling system, with higher production efficiency and consistent quality control.

The continuous casting process can reduce energy consumption, increase production speed, and adapt to automated control to ensure the stability and efficiency of stainless steel production. Therefore, the continuous casting process has become the mainstream method for large-scale stainless steel production, especially for mass production of various types of steel billets, providing ideal raw materials for subsequent rolling and forming.

Hot rolling

Hot rolling is the process of heating a steel billet to a certain temperature and then repeatedly rolling it into the desired specifications and shapes through a rolling mill. The purpose of the hot rolling process is to plastically deform the steel billet, reduce its thickness, and improve the mechanical properties of stainless steel. Usually, the hot rolling temperature is controlled between 1000°C and 1200°C.

Stainless steel after hot rolling can be made into products of different shapes, such as plates, strips, bars, rods, etc. The hot rolling process can not only improve the processing properties of stainless steel, but also further improve its surface quality.

The main steps of hot rolling include:

Heating: heating the steel billet to an appropriate temperature to ensure that it has sufficient plasticity.

Rough rolling: After the initial rough rolling, the thickness of the steel billet will gradually decrease, and the shape begins to approach the target specifications.

Finishing rolling: further reduce the thickness of the steel through the finishing mill and improve its surface quality to meet the specified specifications.

Cold rolling

Cold rolling is the further processing of hot-rolled stainless steel, which is pressed into thinner and flatter steel by applying greater pressure at room temperature. Cold-rolled stainless steel usually has better surface finish and more precise dimensional control.

The advantage of cold-rolled products is that the thickness and size of the product can be precisely controlled, while obtaining higher strength and smoother surface. Cold-rolled products are widely used in home appliances, construction, automobiles and other industries.

The cold rolling process includes:

Annealing: Since the hardness of steel increases during the cold rolling process, annealing is usually required to soften the material in order to improve its machinability.

Pickling: There will be oxide scale on the surface of stainless steel after cold rolling. The pickling process removes surface impurities by using acid solution to keep the surface clean and flat.

Coating: Some stainless steel products also need to be coated or plated to enhance their corrosion resistance or decorative effect.

Stainless Steel Surface Treatment

The surface treatment of stainless steel products can not only improve its appearance, but also enhance its corrosion resistance and wear resistance. Common surface treatment methods include:

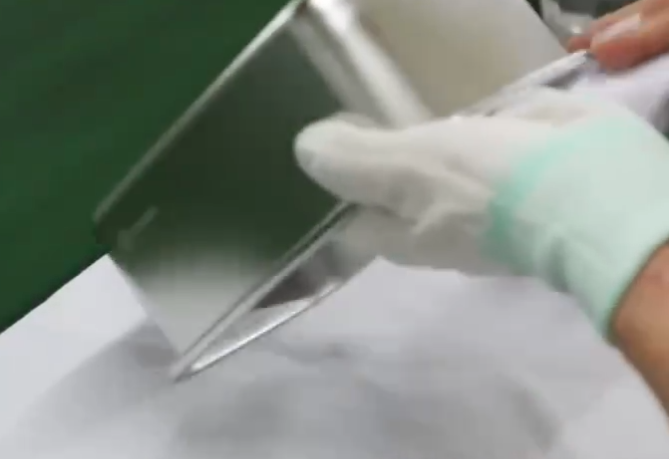

Polishing: The polishing process makes the stainless steel surface smoother and brighter, which is often used in stainless steel tableware, decorative parts and other products.

Sandblasting: The stainless steel surface is treated by spraying sand particles to form a matte effect, which is usually used in kitchen equipment or exterior wall decoration materials.

Coating treatment: The stainless steel surface can be chrome-plated, nickel-plated, sprayed and other treatments to improve its corrosion resistance and appearance.

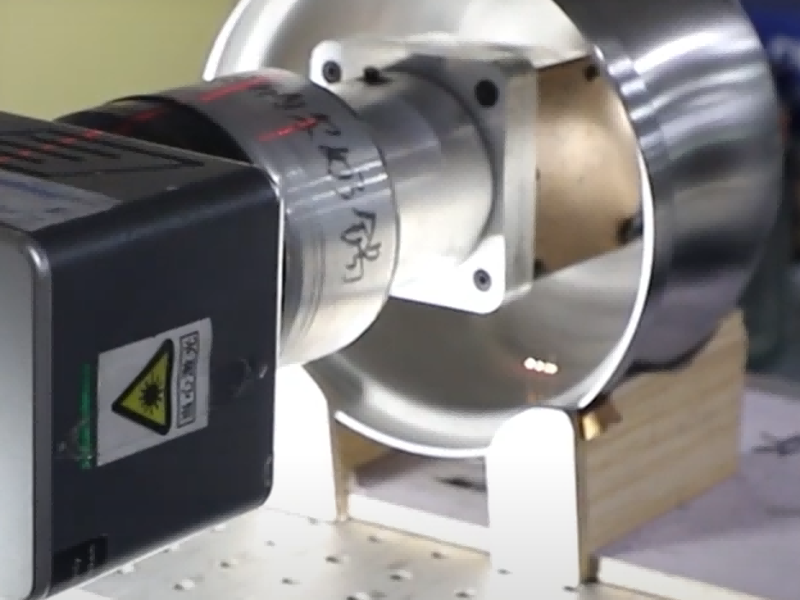

Cutting and Processing

According to different needs, stainless steel products also need to undergo post-processing processes such as cutting, stamping, bending, and welding. For some products with complex molding requirements, such as stainless steel tableware, kitchen utensils, building materials, etc., customized processing may be required according to specific shapes.

In this link, the stainless steel material will be cut into specific sizes and shapes, welded or spliced, and finally formed into a finished product that meets the design requirements.

Inspection and Packaging

The production process of stainless steel products needs to be strictly inspected at the end. By inspecting the size, surface, physical properties, chemical composition and other aspects, ensure that the product quality meets the standard requirements. Common inspection methods include:

Dimension measurement: During the production process, accurate dimensions are the basis for ensuring that the stainless steel lunch box can be used and assembled normally. The length, width, height and other dimensions of each lunch box will be accurately measured to ensure that they meet the design requirements.

Surface inspection: Check for defects such as cracks, scratches, oxidation, etc. Since the surface of the stainless steel lunch box is in direct contact with food, it is crucial that the surface is smooth and flat. All lunch boxes are polished and polished before leaving the factory to ensure that there are no sharp edges and burrs to avoid scratching hands or causing other inconveniences in use.

Performance testing: Test its tensile strength, hardness, corrosion resistance and other properties. One of the main advantages of stainless steel lunch boxes is its corrosion resistance, especially when in contact with food. Through methods such as salt spray testing, test whether the lunch box can resist oxidation and corrosion in different environments to ensure that it can remain in good condition after long-term use.

Summarize

The production of stainless steel products involves many links, from material selection, smelting, forming to processing, surface treatment, quality inspection, and packaging. Each step requires meticulous control of quality and technology. The raw materials are smelted into alloy liquid, and then cast or rolled into the required shape. Cold processing and surface treatment improve performance, corrosion resistance and appearance to meet standards and customer requirements.

Modern production focuses on environmental protection and energy saving, improving efficiency and quality. Finally, after strict inspection and exquisite packaging, stainless steel products are perfectly delivered and widely used in many fields, improving the quality of life and promoting economic development.

About Moya

Moya is a leading stainless steel food container manufacturer with 30 years of manufacturing experience. As a company providing OEM and ODM services, we are able to provide personalized design, size, color and function customization according to customer needs. Whether it is large-scale mass production or small-scale customization, Moya can provide efficient production processes and flexible supply solutions.